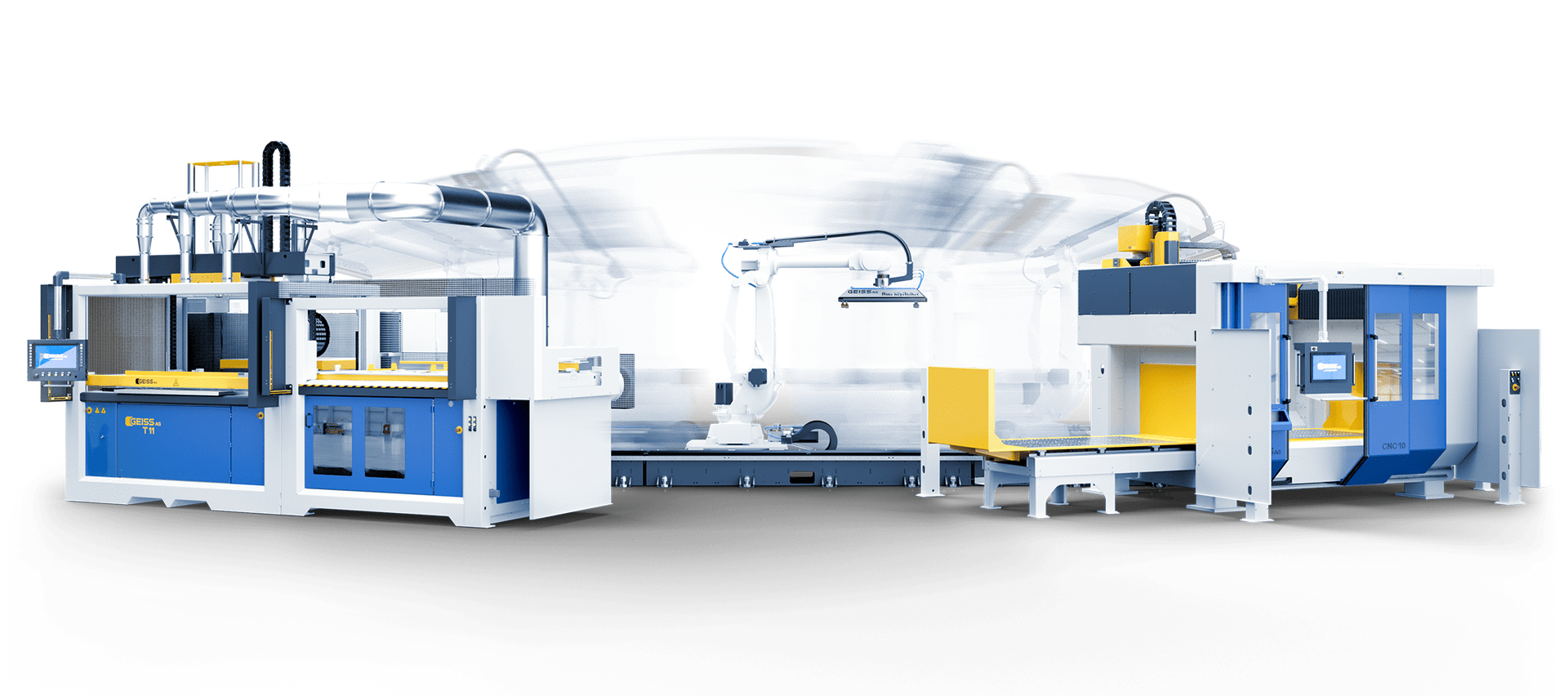

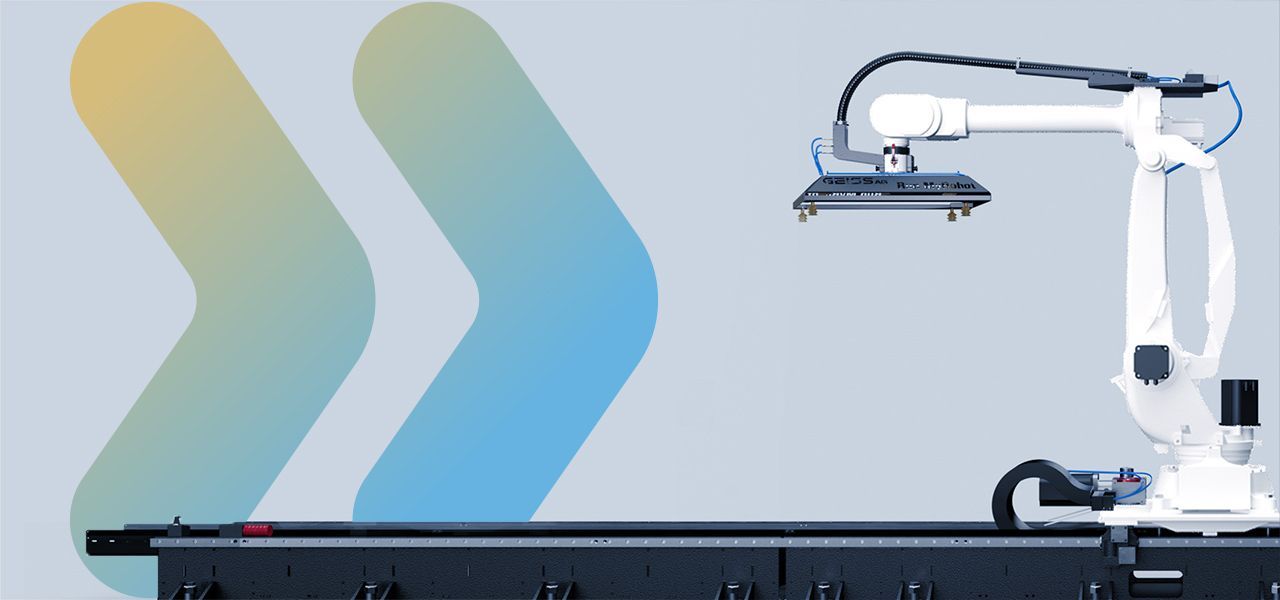

Advanced Robotic Integration

Description:

Elevate your production line with our 'Run My Robot' system, where sophisticated robotics merge with your existing machinery to enhance efficiency and precision. Through the seamless interaction of robots with thermoforming and CNC operations, we provide a smart solution that minimizes manual intervention while maximizing output and consistency.

Advantages of Run My Robot

Streamlined Operations

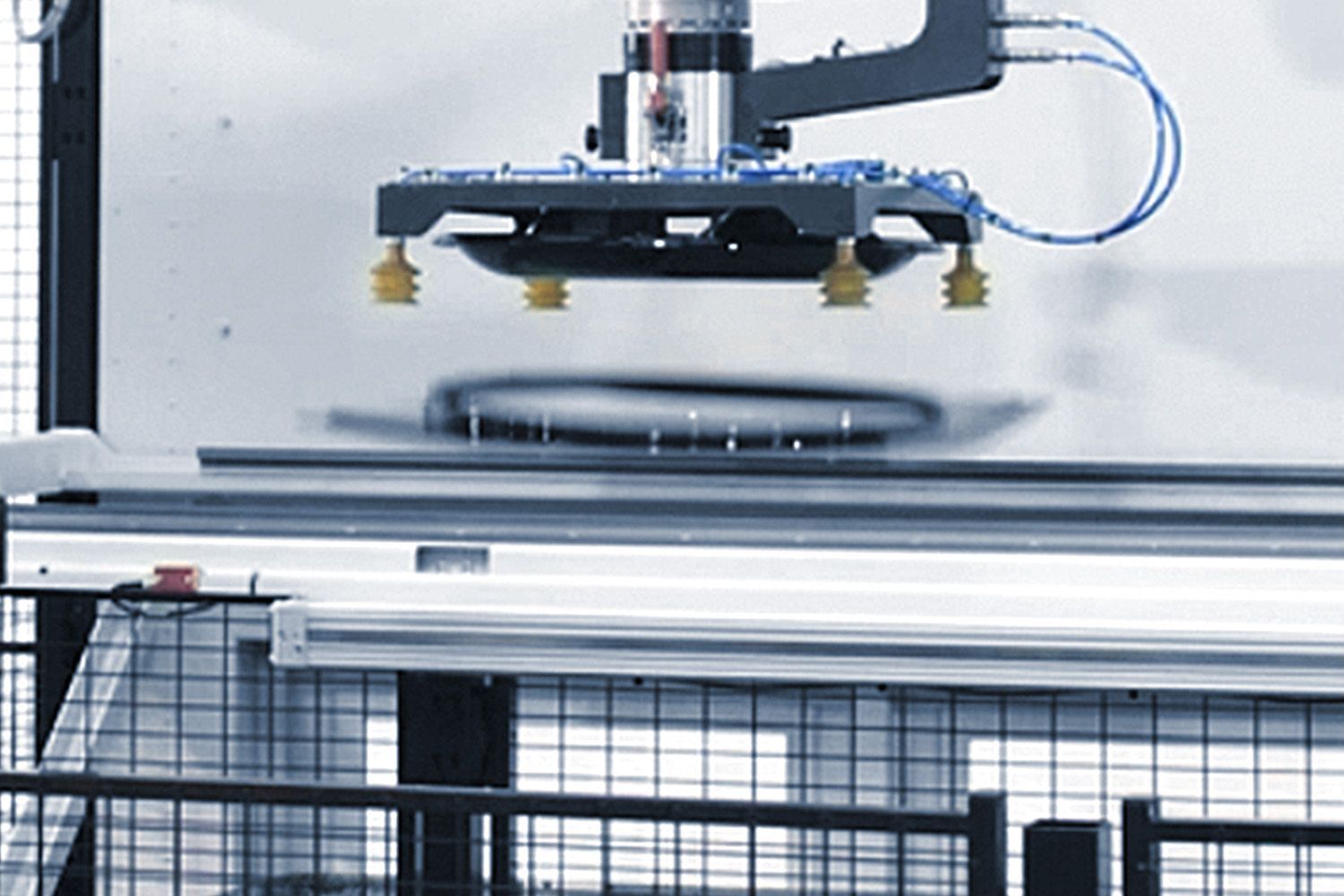

The RmR system automates the transfer and handling of components, significantly reducing cycle times and increasing throughput.

Waste Reduction

Automated processes ensure precise movements and handling, resulting in lower waste levels and optimizing material usage.

Customizable Control

Utilize the parametric control functionality to tailor robot operations to your specific needs, enabling a flexible and adaptive manufacturing environment.

Smaller Footprint

Button

ButtonWith the RmR principle, we can remove the need for WIP storage and handling which significantly reduces the overall footprint of a production operation and ensuring minimal scrap rate.

Features

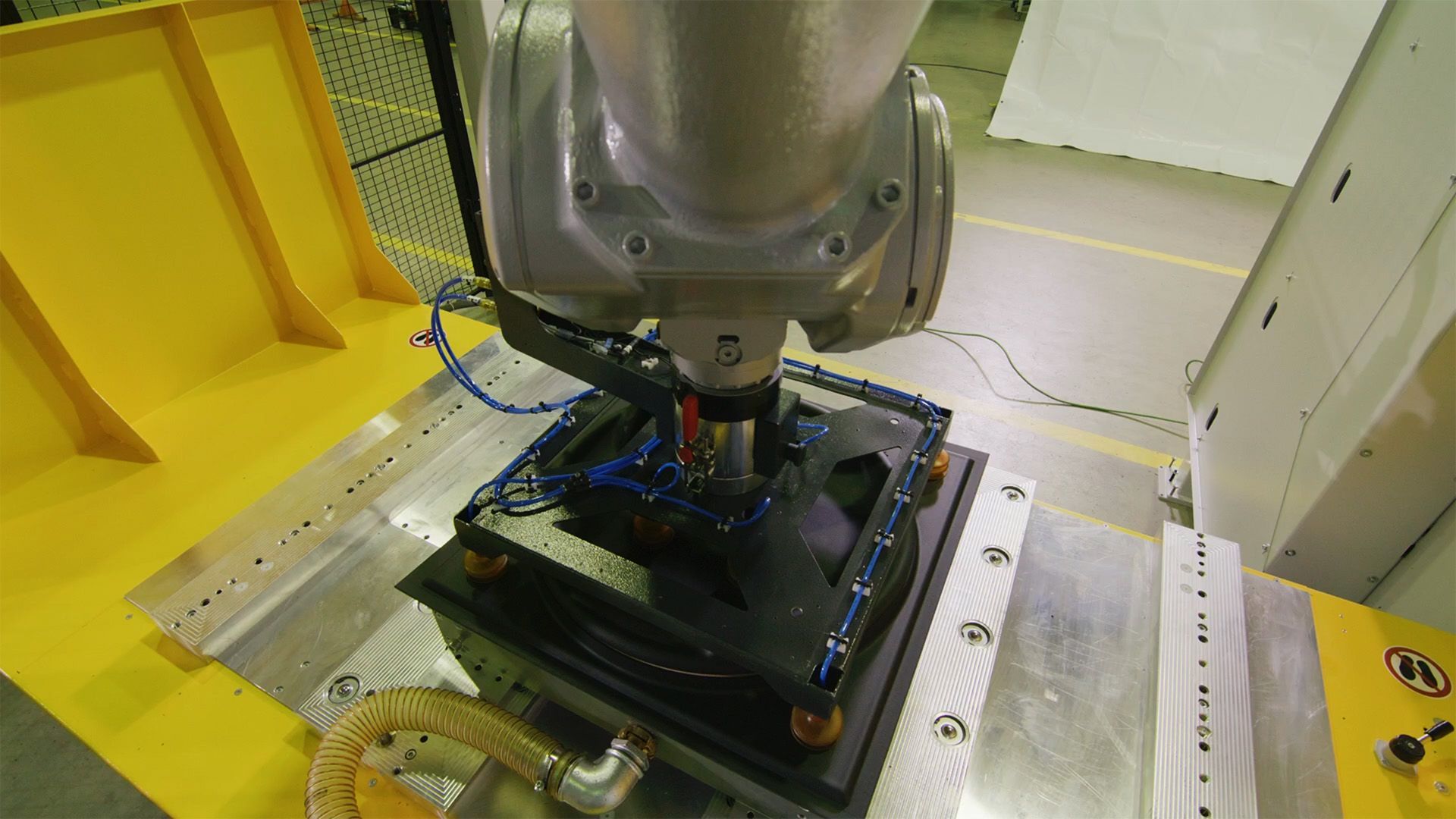

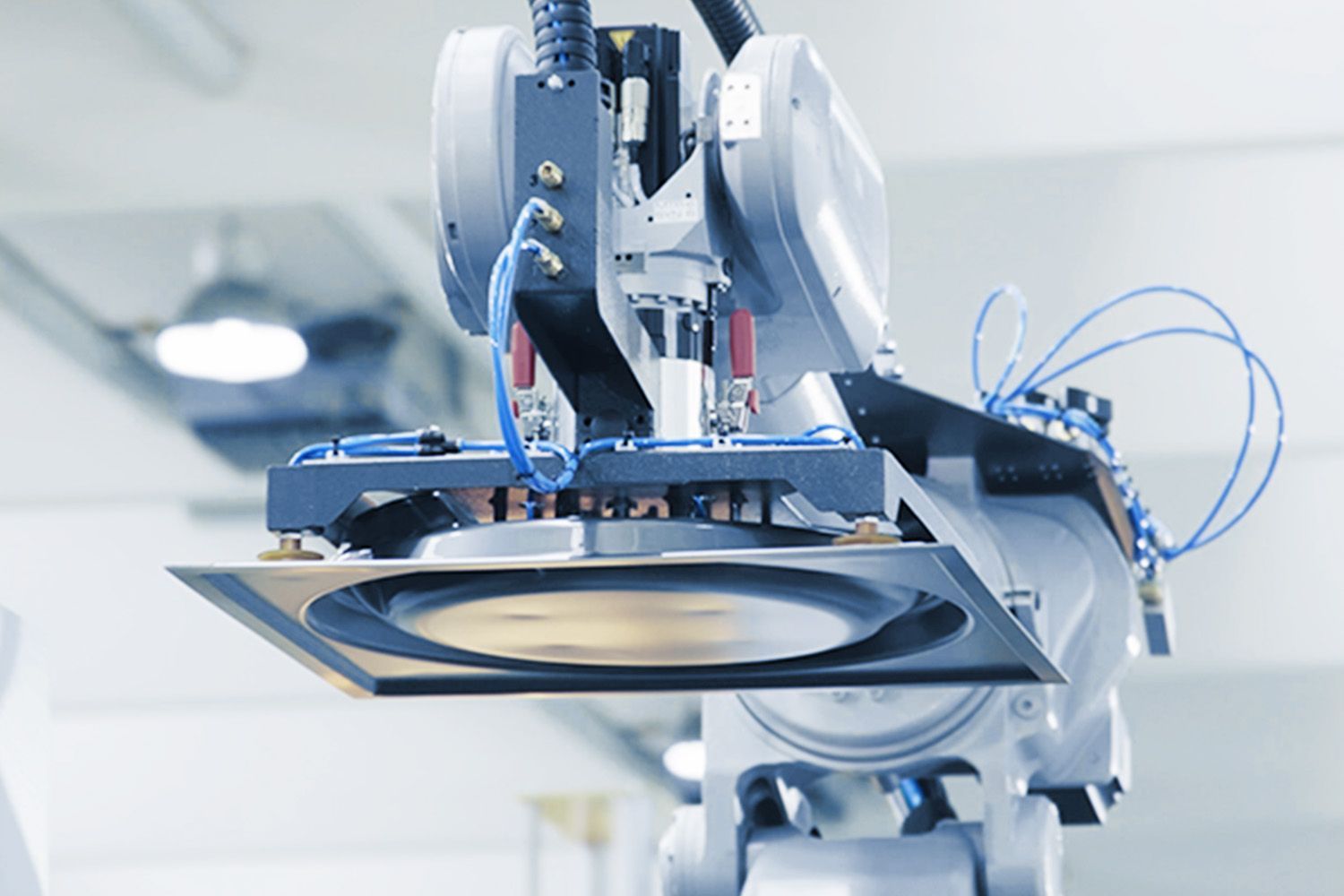

Seamless Transfers

RmR expertly automates the transfer of components between stages, ensuring a smooth and continuous workflow.

Efficient Material Disposal

This innovative system handles the removal of clamping edges and cut-outs, streamlining the disposal process for maximum efficiency.

Intuitive Parametric Control

Equipped with parametric control, our system simplifies the adjustment of robot movements, allowing for easy customization and precise automation in your production line.

For more information about the Run My Robot, call us at (860) 605-8643 or complete the form.

Why Choose Us

Over 75 Years of Industry Experience

Long-Term Cost Saving Investment

Lowest Cost Per Part Produced

Optimized Operational Efficiency

Substantial Savings in Energy Consumption

Reduced Material Usage & Lowest Scrap Rate

Highly Customizable Solutions

Professional Service & Support

Frequently Asked Questions

What capabilities does the Run My Robot system provide for my production line?

The Run My Robot system enhances your production capabilities by enabling seamless robot integration into thermoforming or trimming processes. It facilitates the transfer of components between machines and automates the disposal of clamping edges and cut-outs, thus streamlining your manufacturing workflow.

How user-friendly is the parametric control in the Run My Robot system?

The Siemens SINUMERIK Run My Robot function offers user-friendly parametric control, making it easy for operators to customize robot movements. This feature allows for quick adjustments and fine-tuning, reducing the time typically required for programming and setup.

Can the Run My Robot system be adapted to my existing machinery?

Yes, the Run My Robot system is designed for flexibility and can be integrated with your existing machinery. This adaptability allows for a customized automation solution that enhances your current equipment's efficiency without the need for substantial new investments.