Check our Plastics Machinery & Manufacturing Magazine's article featuring the upgrades on the T11 machine.

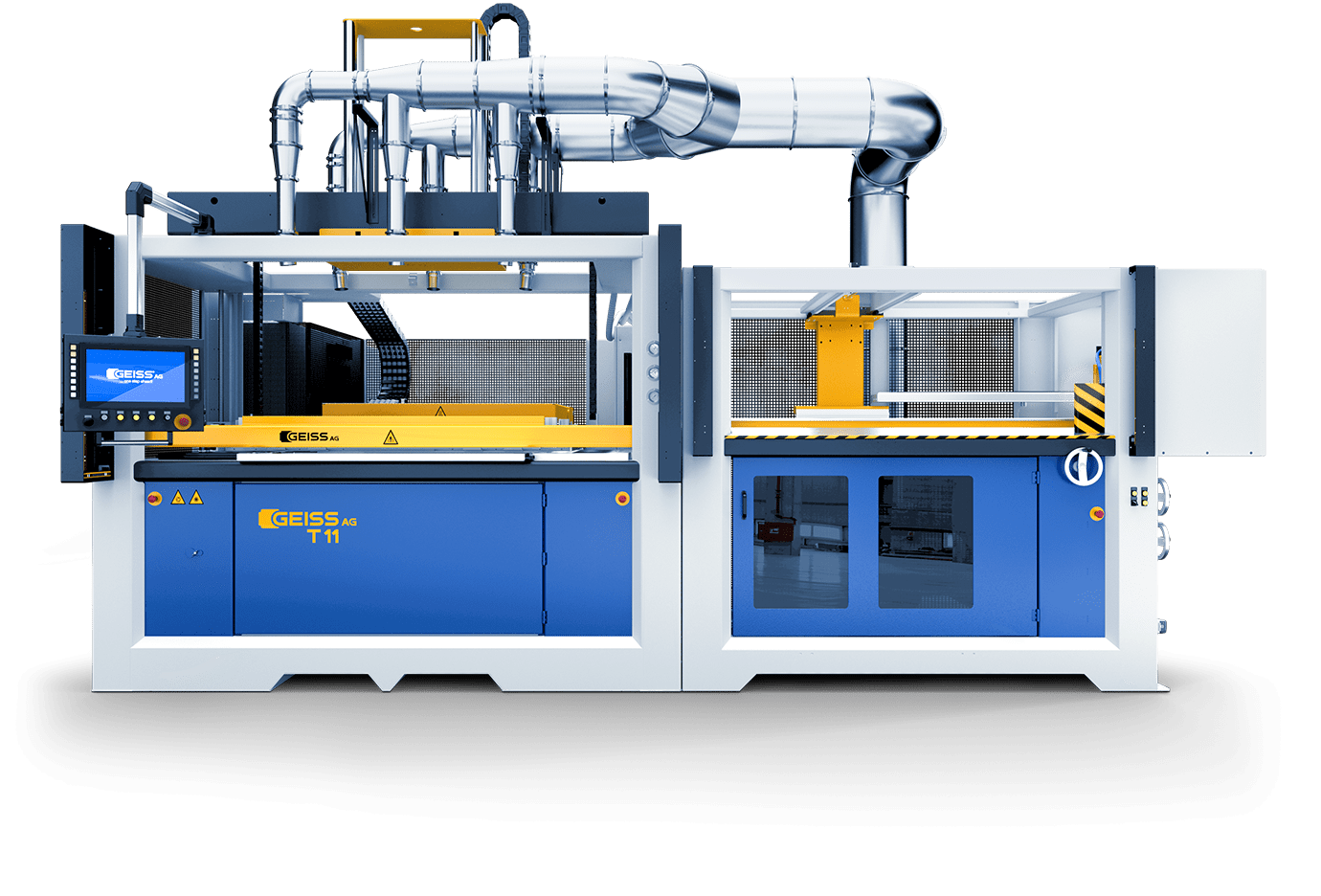

The T11 Thermoforming Machine

Description:

The T11 exemplifies the pinnacle of Geiss, LLC's technological advancements in thermoforming. It distinguishes itself as the most potent thermoforming machine we offer, featuring notably shorter cycle times and a sleek, compact build.

Advantages of Our T11

Control Concept

The T11 revolutionizes thermoforming with a smartphone-simple control interface, blending advanced technology with unparalleled user-friendliness. Its touchscreen simplifies adjustments and setups through intuitive interactions and customizable displays, ensuring an efficient and straightforward operating experience.

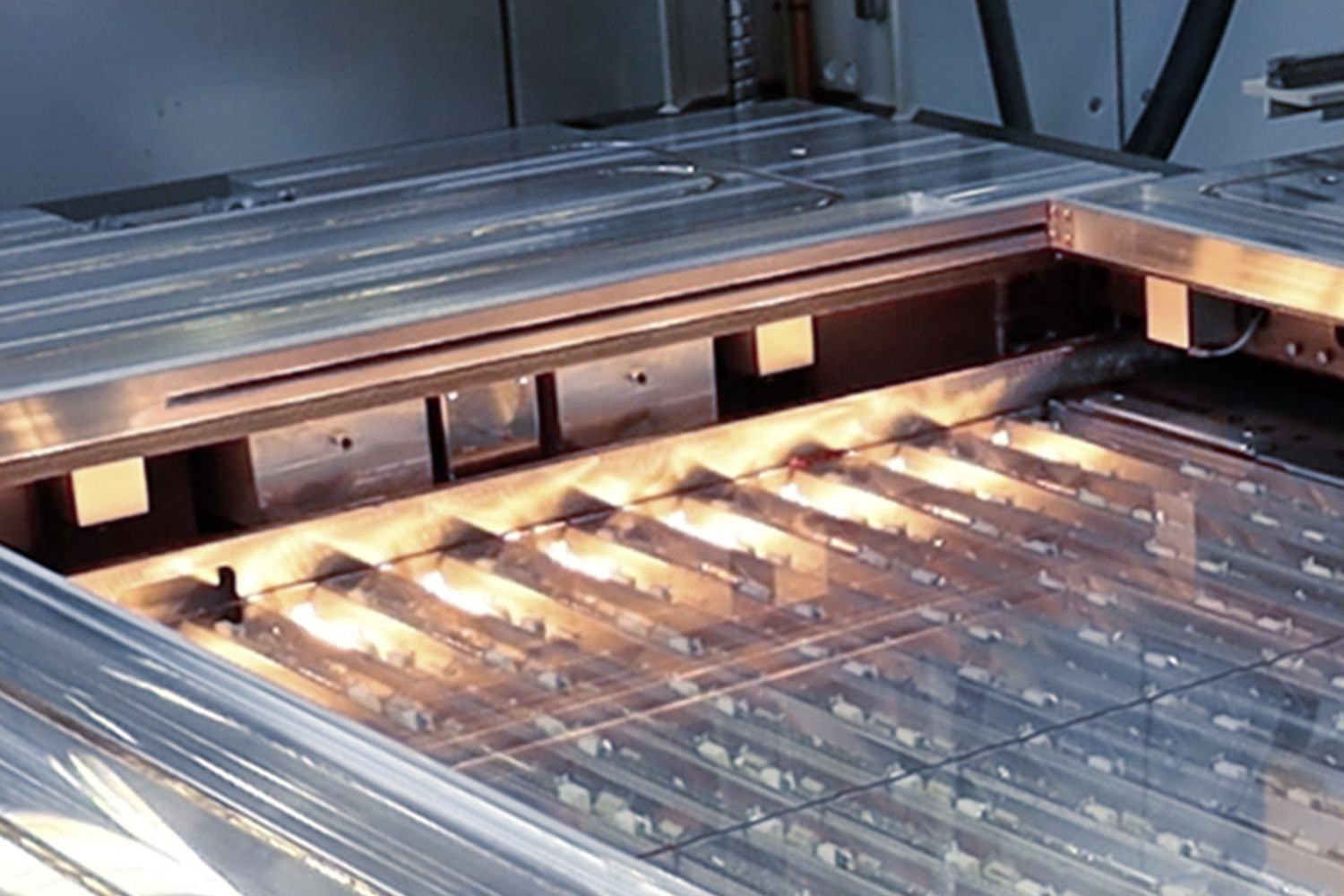

Heating Control

The T11 brings an innovative approach to heating control, introducing the ability to establish individual heating zones for precise temperature management. Utilizing pyrometers, it meticulously monitors the material temperature, ensuring the material is heated optimally. This tailored heat management system guarantees consistently high-quality outcomes, especially vital in multi-cavity production scenarios, elevating product quality to new heights.

Robot Integration

The T11 automation streamlines the integration of robot control within the thermoforming machine itself, foregoing the necessity for additional hardware and thus reducing costs. Managed entirely through the T11's Human-Machine Interface (HMI) with seamless integration of product data, this approach enhances efficiency and offers the convenience of a single contact point for the whole system, optimizing both operation and maintenance.

Features

User-Friendly Interfaces

Geiss, LLC thermoforming machines feature advanced user interfaces, enabling precise control for optimal operational efficiency and quality.

Consistent Heating Control

Our machines are designed with high performance heating systems that guarantee consistent quality across all thermoformed products.

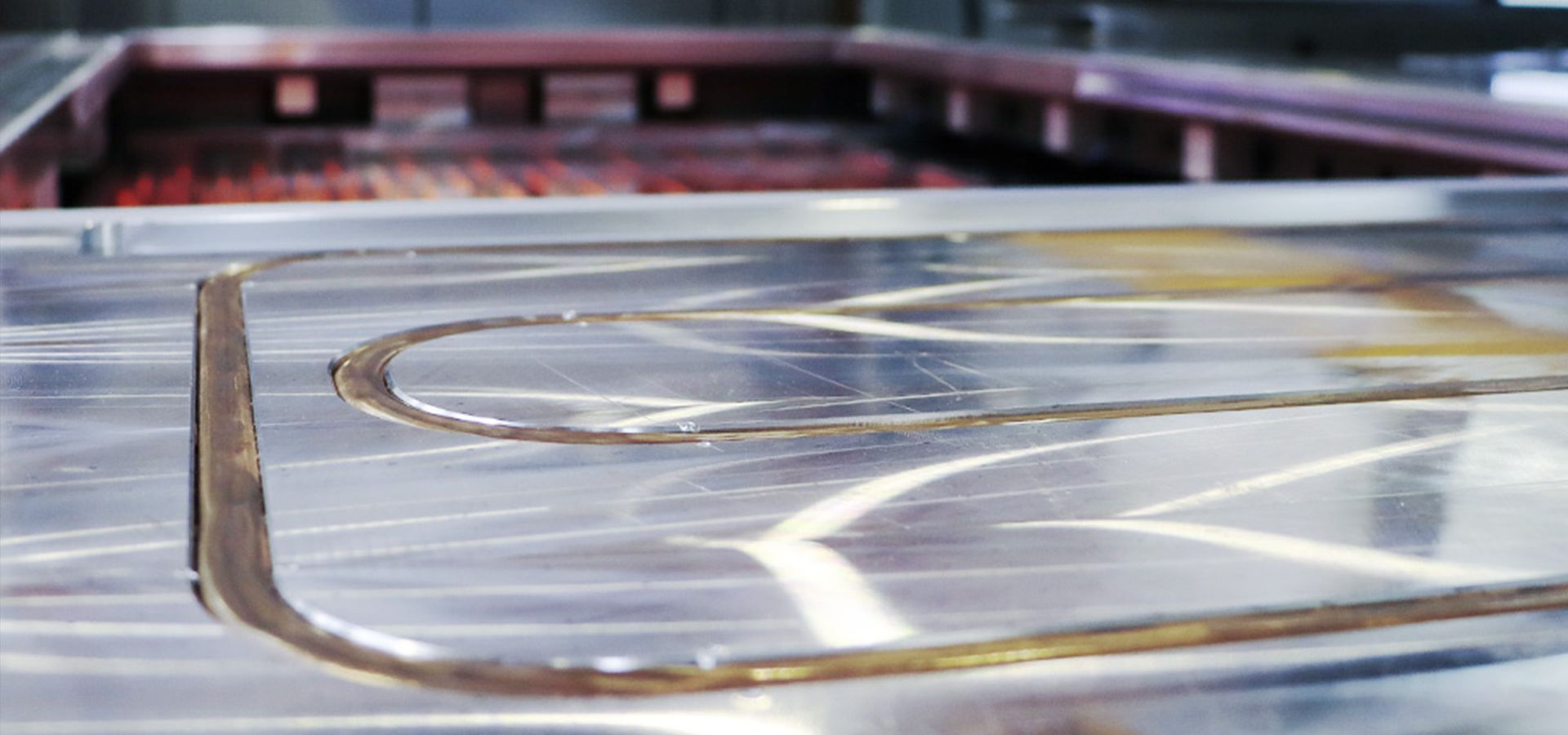

Precision Forming Technology

Geiss thermoforming systems set the standard for precision and performance. With advanced process control, they deliver consistent, high-quality forming results even on the most complex parts. The T11 platform is fully customizable in size, configuration, and application to meet specific production requirements. It supports every major thermoforming process, including cut sheet, roll-fed, twin-sheet, pressure forming, and compression molding, ensuring maximum flexibility for diverse manufacturing needs.

Robust Construction

Every Geiss, LLC machine is built to last, featuring durable construction that withstands the rigors of heavy industrial use.

Advanced Cooling Systems

Geiss, LLC incorporates cutting-edge piping systems, optimized for uniform heat dissipation resulting in precise finished part geometries.

For more information about our thermoforming systems, call us at (860) 605-8643 or complete the form.

Why Choose Us

Over 75 Years of Industry Experience

Long-Term Cost Saving Investment

Lowest Cost Per Part Produced

Optimized Operational Efficiency

Substantial Savings in Energy Consumption

Reduced Material Usage & Lowest Scrap Rate

Highly Customizable Solutions

Professional Service & Support

Frequently Asked Questions

What are the key advantages of the T11 thermoforming machine compared to its predecessor, the T10?

The T11 offers significant improvements in control concept, heating control, and robot integration, leading to enhanced efficiency and productivity.

How does the T11 thermoforming machine integrate robot control?

The T11 incorporates robot control directly within its system, eliminating the need for separate hardware and software and enabling efficient automation through its human-machine interface (HMI) with automatic product data integration.

What customization options are available for the T11 thermoforming machine?

The T11 supports parametric design for near infinite sizes above a minimum dimension, with flexibility in tool height and the ability to be upgraded with a wide range of Geiss options for specialized applications.

What are the primary benefits of using the T11 thermoforming machine in manufacturing?

Users can expect the maximum possible throughput of the highest quality parts with the minimum consumption of labor, materials, energy, and floorspace. All contributing to the lowest cost-per-part produced.