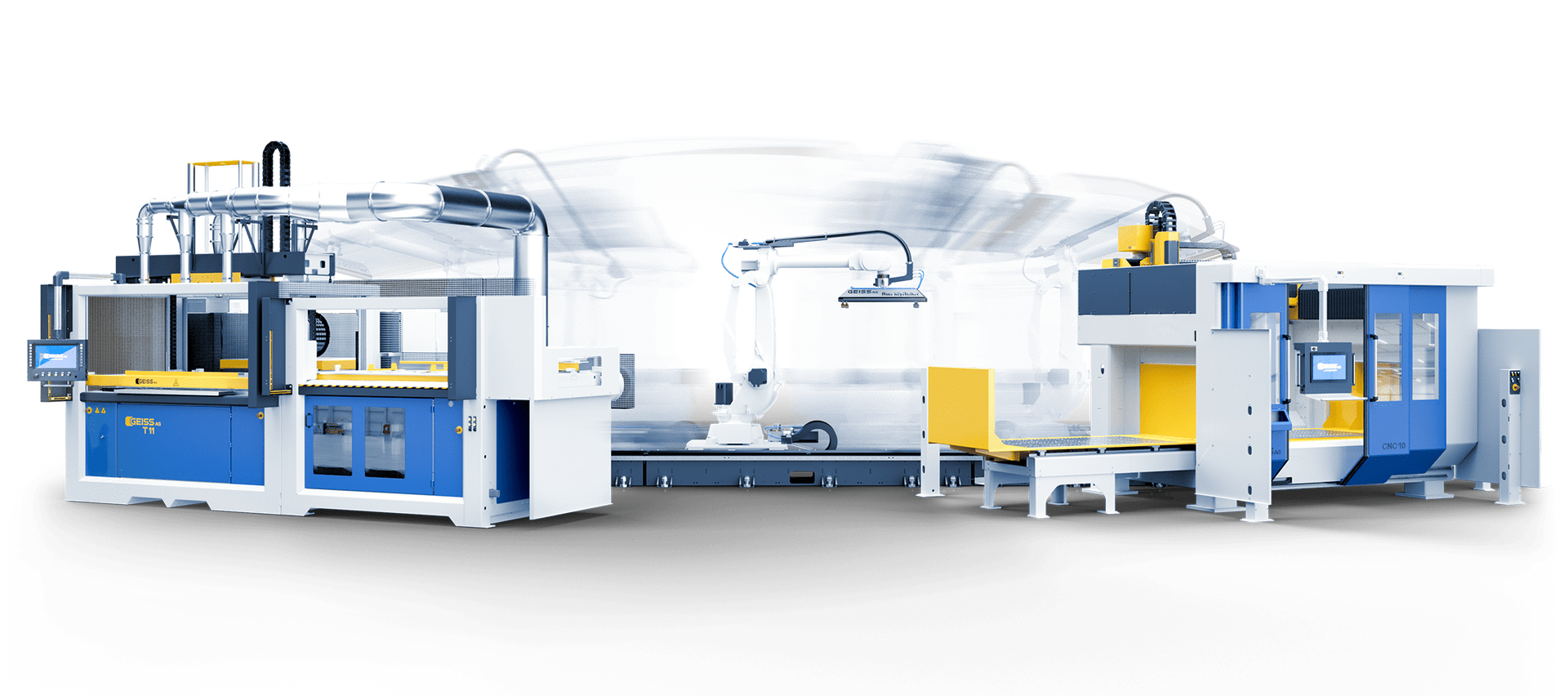

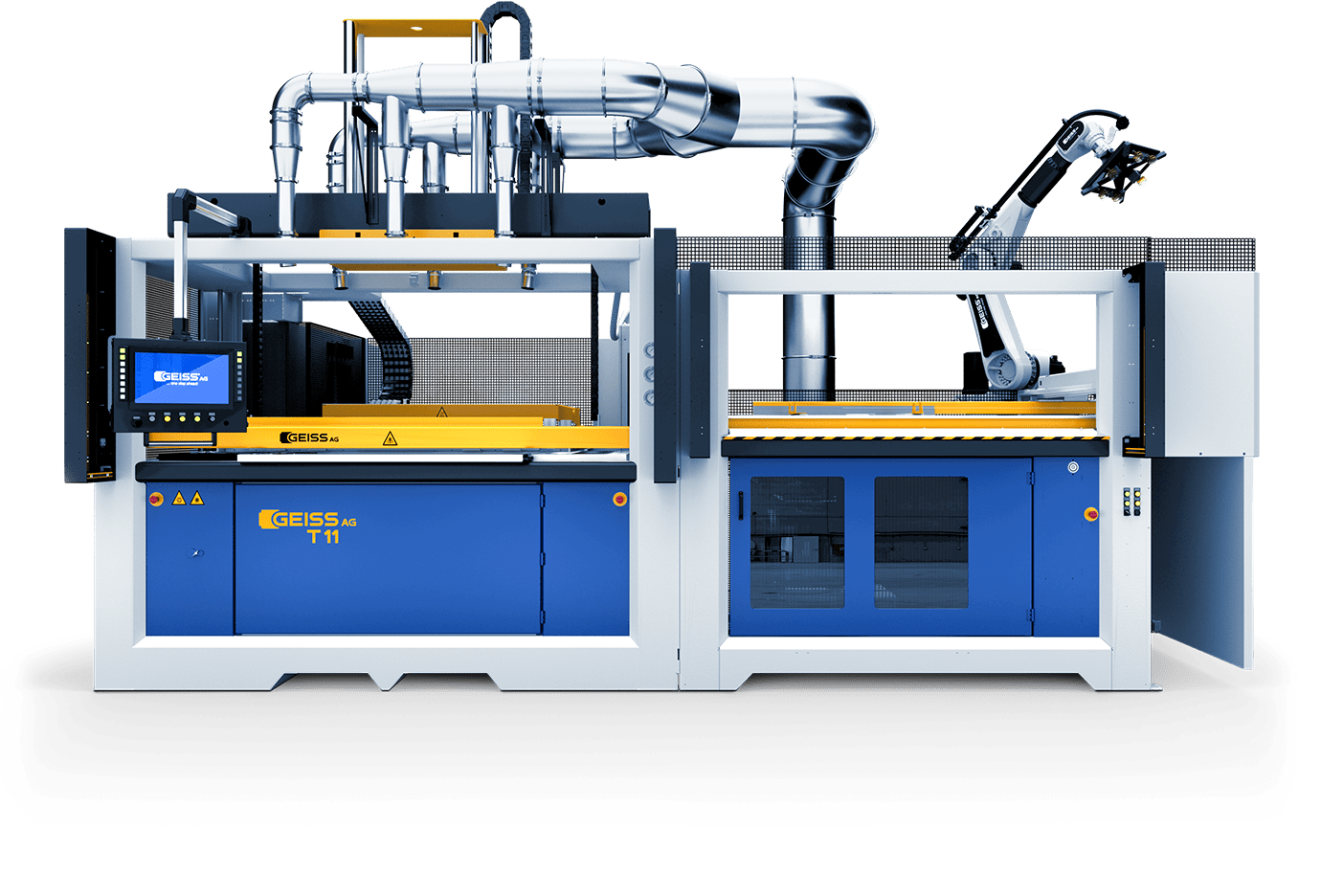

Transformative Solutions

Embrace the future of manufacturing with Geiss's tailored automation systems, designed to elevate efficiency and streamline your production workflow.

Products

For more information about our products, call us at (860) 605-8643 or complete the form.

Why Choose Us

Over 75 Years of Industry Experience

Long-Term Cost Saving Investment

Lowest Cost Per Part Produced

Optimized Operational Efficiency

Substantial Savings in Energy Consumption

Reduced Material Usage & Lowest Scrap Rate

Highly Customizable Solutions

Professional Service & Support

Frequently Asked Questions

What automation solutions does Geiss, LLC offer for thermoforming and CNC machining?

Geiss, LLC provides a range of automation solutions tailored to enhance the efficiency of thermoforming and CNC machining processes. This includes robotic technology for material handling, gantry systems for seamless workflow integration, and custom automation setups like Run My Robot, T11 Automation, and TT-IN-ONE to cater to specific production needs.

How can automation improve my manufacturing process?

Automation can significantly boost productivity, consistency, and safety in your manufacturing process. By reducing manual handling, it minimizes errors and waste, speeds up production times, and allows for 24/7 operation. Additionally, automation can lead to better use of materials and resources, thus optimizing overall operational costs.

Can Geiss, LLC automation be integrated with my existing production line?

Yes, Geiss, LLC's automation systems are designed with flexibility in mind to complement your existing setup. Our experts can customize automation solutions to integrate with your current production line, ensuring a smooth transition and minimal disruption to your manufacturing processes.