Check our Plastics Machinery & Manufacturing Magazine's article featuring the upgrades on the T11 machine.

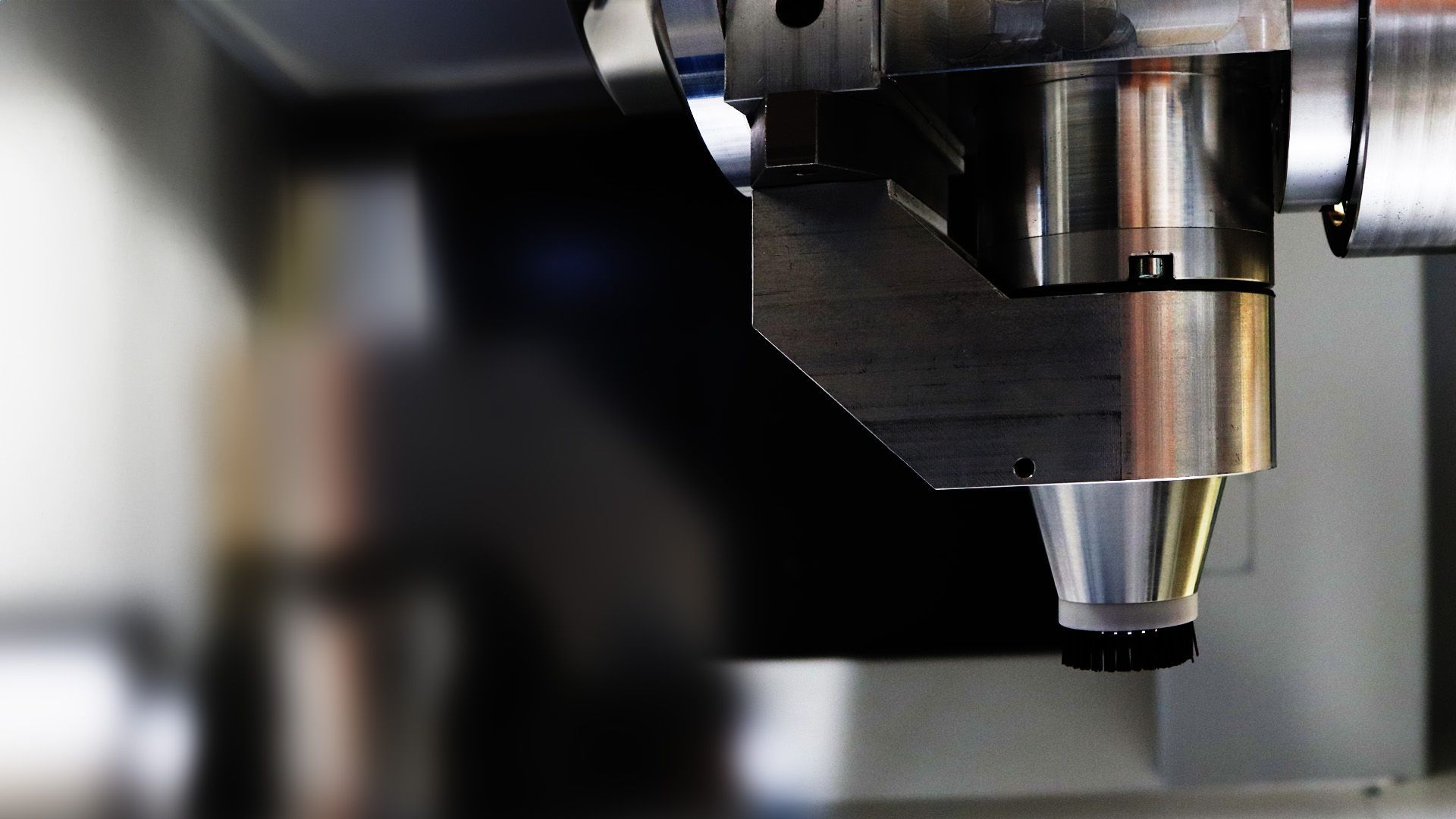

Precision in Every Cut

Description:

Our trim fixture tooling is crafted to deliver unparalleled accuracy in the CNC machining. The fixtures are designed with precision to ensure that each piece is cut with exactness, enhancing the quality and fit of the final product.

Advantages of Our Trim Fixture Tooling

Enhanced Consistency

The meticulous design of our trim fixture tooling allows for consistent reproduction of intricate details across multiple production runs, ensuring uniformity in your project's components.

Material Versatility

Our trim fixture tooling is adaptable to a broad array of materials, maintaining precision cutting for complex designs while preserving the material’s integrity and surface quality.

Efficiency in Production

Our tooling is designed to optimize your CNC machining workflow. By reducing the need for manual intervention, our fixtures streamline the production process, enhancing throughput and reducing cycle times.

Applications

For more information about trim fixture tooling, call us at (860) 605-8643 or complete the form.

Why Choose Us

Over 75 Years of Industry Experience

Long-Term Cost Saving Investment

Lowest Cost Per Part Produced

Optimized Operational Efficiency

Substantial Savings in Energy Consumption

Reduced Material Usage & Lowest Scrap Rate

Highly Customizable Solutions

Professional Service & Support

Frequently Asked Questions

What types of materials can be used with your trim fixture tooling?

Our trim fixture tooling is versatile and capable of handling a wide array of materials, including plastics, composites, and lightweight metals. The rigidity and precision of our fixtures accommodate both soft and hard materials to deliver clean cuts and precise edges, tailored to your specific production requirements.

How do your trim fixture tools improve the efficiency of the production process?

Efficiency is a cornerstone of our trim fixture tooling design. With features like quick-change capabilities and precision alignment, our tools minimize downtime and enhance the speed of the production cycle. This ensures a faster turnaround for high-volume manufacturing without compromising on the quality of the finished product.

Can trim fixture tooling be customized for unique product designs?

We specialize in creating custom trim fixture tooling solutions to meet unique design specifications. Our team works closely with clients to understand the intricacies of their products, developing tailor-made fixtures that cater to specific shaping and cutting needs, ensuring a perfect match for every design.