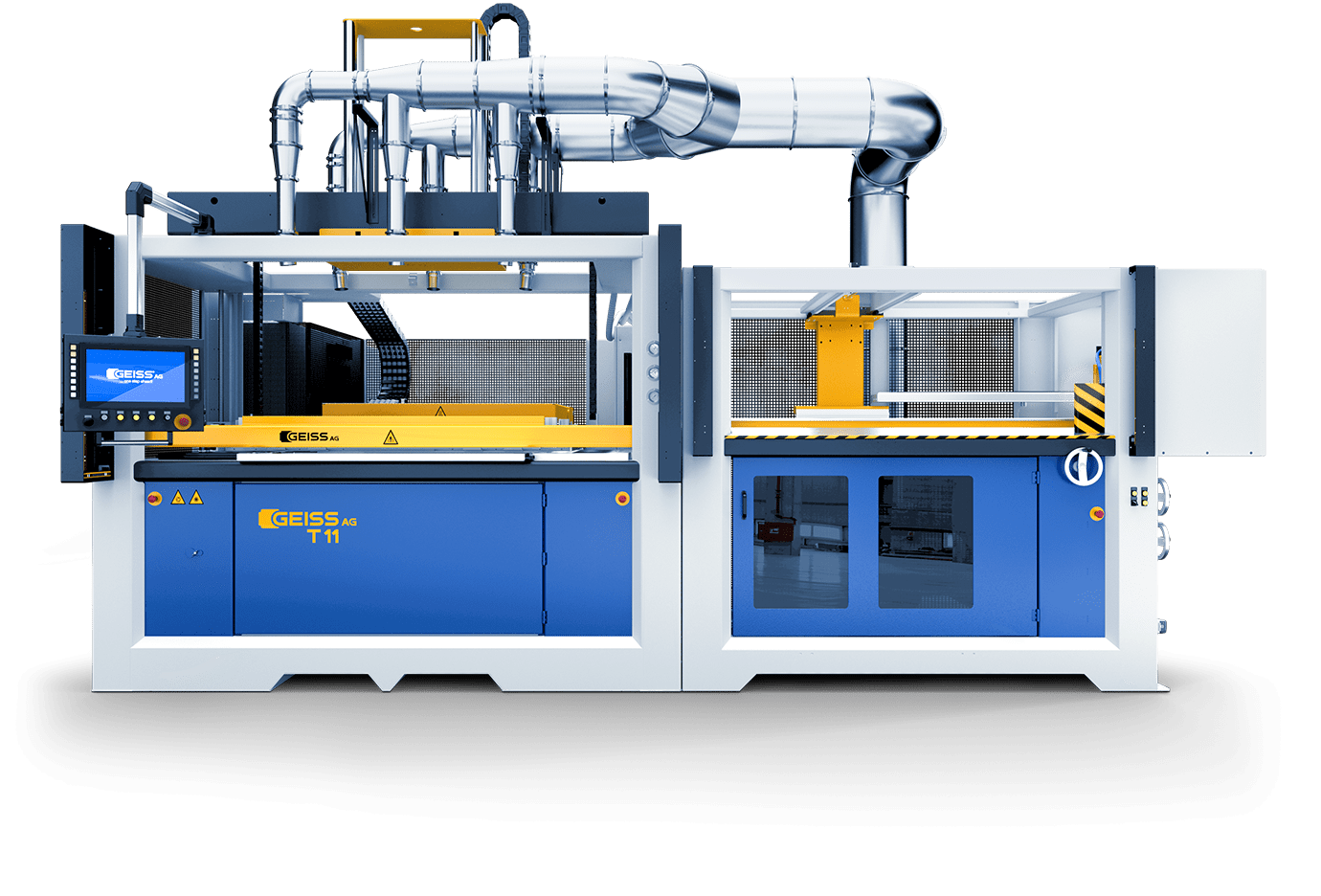

Check our Plastics Machinery & Manufacturing Magazine's article featuring the upgrades on the T11 machine.

Manufacturing Solutions

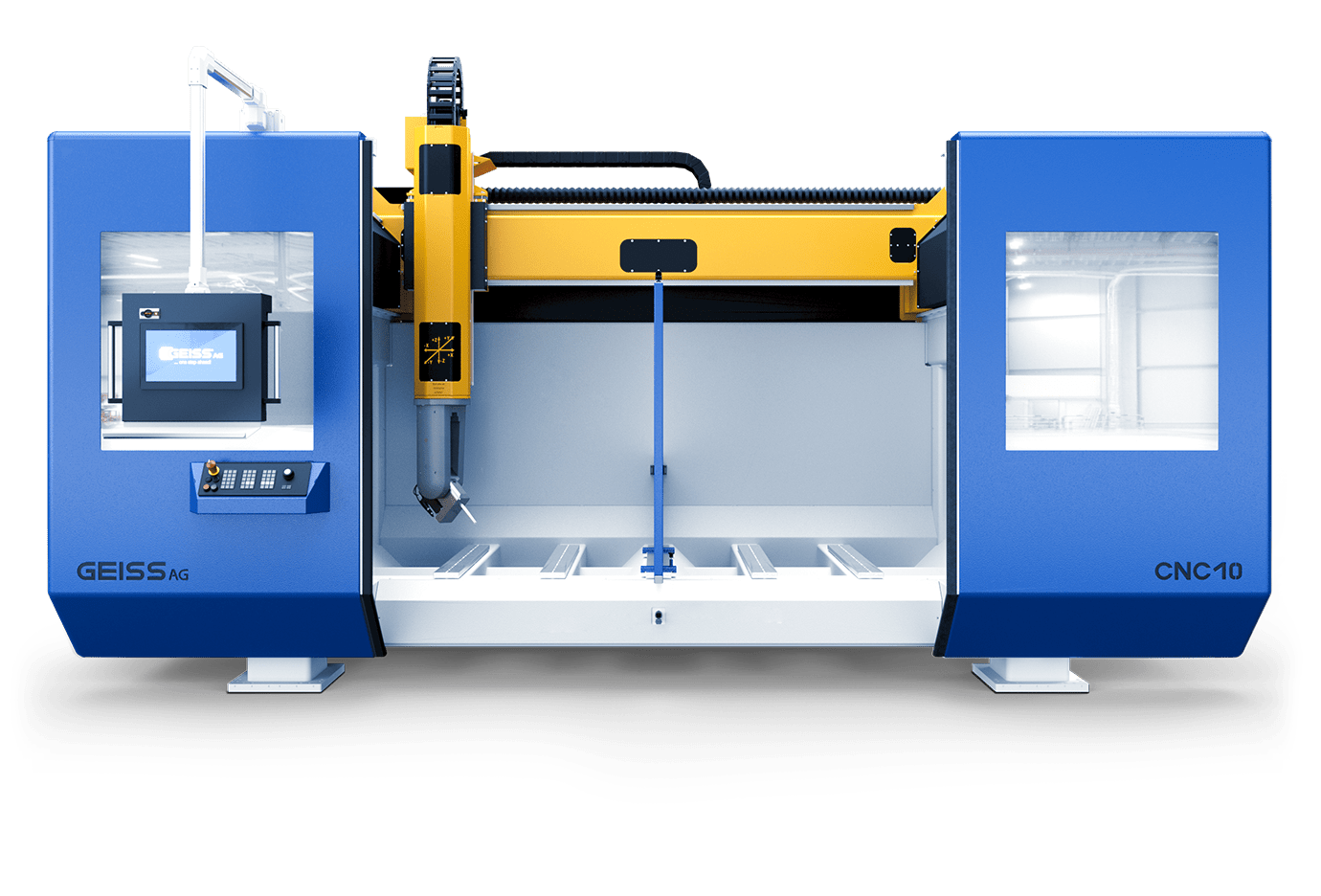

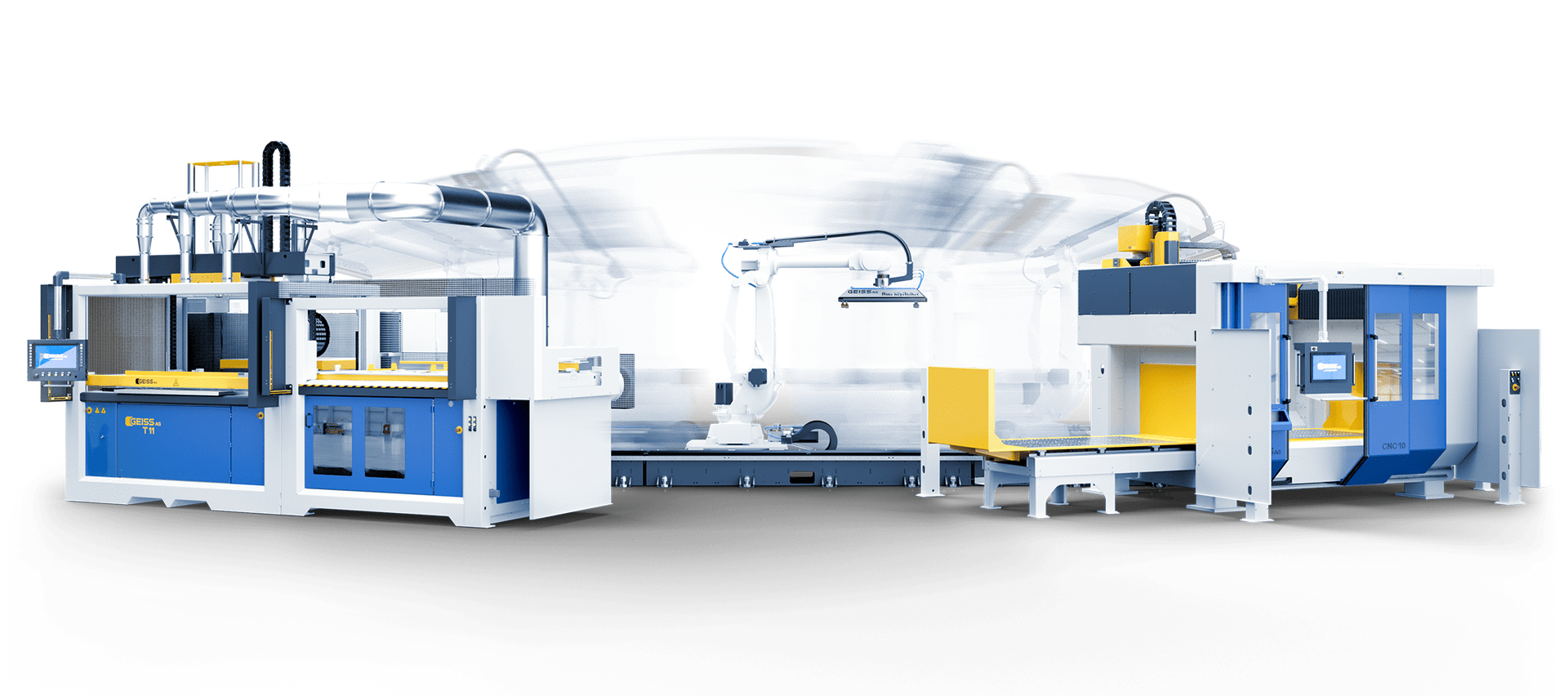

At Geiss, LLC, we offer a variety of high-tech thermoforming equipment and CNC machines, each designed with precision to cater to the specific needs of industries looking for efficiency, reliability, and quality.

Products

For more information about our products, call us at (860) 605-8643 or complete the form.

Why Choose Us

Over 75 Years of Industry Experience

Long-Term Cost Saving Investment

Lowest Cost Per Part Produced

Optimized Operational Efficiency

Substantial Savings in Energy Consumption

Reduced Material Usage & Lowest Scrap Rate

Highly Customizable Solutions

Professional Service & Support

Frequently Asked Questions

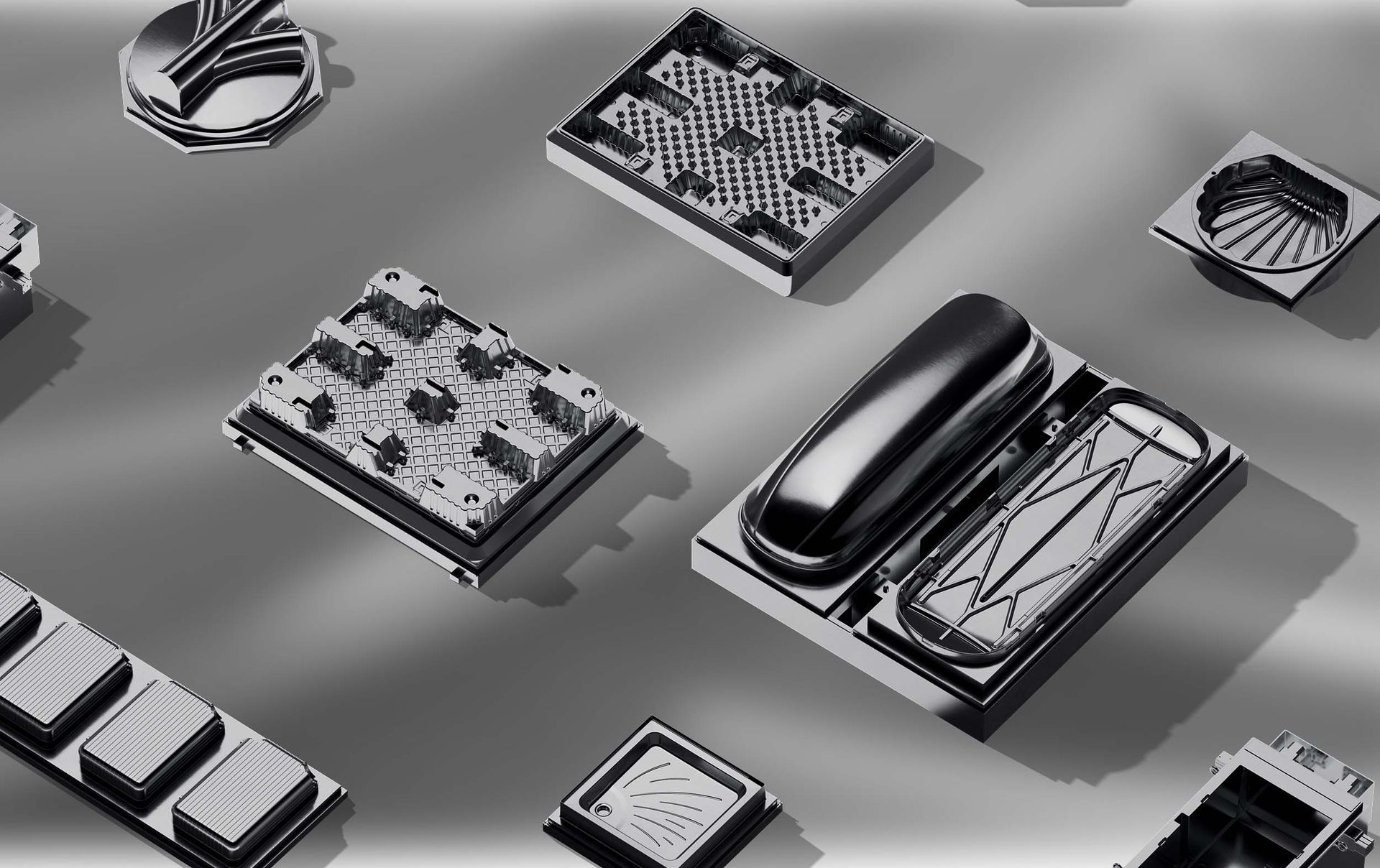

Are Geiss, LLC products customizable for specific applications?

Yes, leveraging our parametric design principle, we can customize our thermoforming and CNC machines to meet the unique demands of your industry's applications.

Can Geiss, LLC machinery handle different materials and thicknesses?

Absolutely, our machinery is designed for versatility, capable of handling a wide range of materials and thicknesses to suit various manufacturing requirements and applications.

How does Geiss, LLC support product integration into existing workflows?

Geiss, LLC provides full support for integrating our products into your existing workflows, including on-site training, installation services, and ongoing technical support to ensure seamless operation.